Description

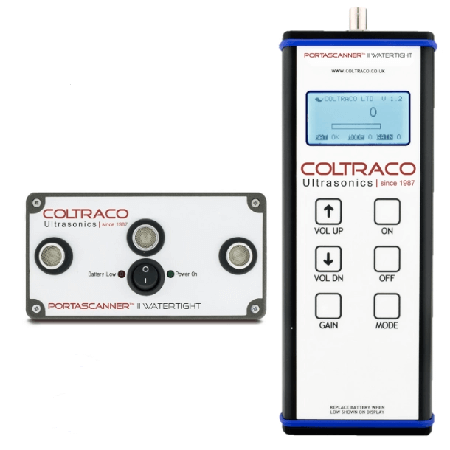

The Portascanner® WATERTIGHT is the original technology developed by Coltraco Ultrasonics to test the integrity of sealed compartments, watertight/weathertight doors, hatch-covers, and multiple cable transit areas with unique dual decibel and linear readings accurate to 0.06mm +/- 0.02mm.

With its unbeaten accuracy and suitability for use by any operator with free training provided and no need for time-consuming, expensive courses, the Portascanner® WATERTIGHT is the easiest way to reliably check for watertightness and weathertightness.

Existing methods for water flow measurement are disruptive, costly, and unreliable. Hose testing, for example, may damage cargo and contribute to the degradation of seals, while violating environmental codes. Meanwhile, the Portascanner® WATERTIGHT is a hand-held instrument that, with minimal training, can be deployed regularly with crew in situ.

The Portascanner® WATERTIGHT is used as a maintenance instrument for watertight seals, doors, cable transits, hatch covers, and bulkheads. It allows maintenance operators to ensure complete watertightness or weathertightness without needing the compartment to be subject to water ingress and can operate with a range up to 50m.

- Know where your leaks are and their significance – know if and when a seal requires replacing

- Improve efficiency and quality of watertight room maintenance – locate leaks, assess their significance, and seal the leaks that matter

- Grants the user the ability to fully assess a compartment or vessel prior to and during transit, meaning risks can be identified as early as possible

- Portable and easy to use in a 7” hand-held tablet format – can be used in-house by crew or by third party maintenance teams

- Ability to determine individual water leakage rates through specific walls, doors, seals etc.

- Ability to determine the exact location of leaks, meaning remedial measures can be taken. This is far more accurate and reliable than procedures such as chalk testing.

- The process is quick and procedural