Description

The ingress of water through leaking hatch covers is a main cause of damage to cargo. It is in the interest of ship owners, managers and insurers to guarantee the cargo hold is watertight, as damaged cargo caused by water leaking through hatch covers often results in large claims against insurance companies and P&I clubs.

CARGO-SAFE™ is an American Bureau of Shipping (ABS) Type Approved hatch cover tester. The CARGO-SAFE™ Ultrasonic Hatch Cover Tester provides a quick and simple method of establishing weather tightness of hatch covers, bow, stern and side doors, but unlike hose testing, has no negative side effects on the port or harbour environment and can be performed in sub-zero temperatures.

UNLIKE HOSE TESTING, THE ULTRASONIC HATCH COVER TESTER:

• is compliant with port and harbour environment management plans as it does not pollute the marine environment

• can locate holes and tears in hatch seals with pinpoint accuracy

• causes no damage to cargo

• can be conducted in sub-zero temperatures

• can be carried out with the cargo in place

• does not interfere with other crew activities.

HOW THE CARGO-SAFE™ ULTRASONIC HATCH COVER TESTER WORKS…

The principle for ultrasonic testing is very simple. After the hatch covers are closed, a transmitter generating an ultrasonic signal is placed in the cargo hold (empty or loaded with cargo) emitting ultrasonic waves. The surveyor or operator then uses the CARGO-SAFE™ ultrasonic receiver to ‘listen’ from the outside of the hold and detect any ultrasonic sounds that pass through holes in the hatch cover sealing system with pin-point accuracy. The size of the problem can be established from the strength of the signal detected.

The CARGO-SAFE™ hatch cover leak detection system has three levels of emitters: upper, lower and vertical. This means that all the ultrasound is directed to the hatch covers, optimising its effectiveness. The diagram shows the dispersion pattern of the ultrasonic sound emanating from the CARGO-SAFE™ Transmitter. The high sound pressure level is ample to fill the largest of holds enabling reliable and accurate readings.

1. The CARGO-SAFE™ Transmitter is placed in the cargo.

2. On the deck, with the hatches closed, the microphone and headphones are plugged into the Receiver.

3. The surveyor begins to inspect the hatch, holding the microphone against the hatch seals. Any gaps through which air or water can pass will allow the ultrasonic signal to pass and can be detected.

4. The display on the Receiver shows the decibel level of any ultrasound leaking through the hatch seals. It can also be heard through the headphones.

5. The flexible microphone and the extension arm allow the position of any potential leaks to be identified with pin-point accuracy. The size of the problem is established by the strength of the signal detected.

OTHER CARGO-SAFE™ FEATURES:

• Each CARGO-SAFE™ ultrasonic hatch cover tester comes with its own certificate of calibration and conformity.

• No training needed to operate – full instructions given.

• Simple to use, fast and accurate results.

• Switchable between dB (decibels) and percentage of OHV (Open Hatch Value).

• Does not need frequent periodic recalibration.

• Suitable to be carried as hand luggage on aircraft.

• The most powerful ultrasonic hatch tester available on the market with a 157 dB transmitter – suitable for any size of ship.

• 3 year warranty on Receiver and Transmitter units.

• Durable and storm proof, environmental protection to IP66.

• LCD display allows ease of reading in bright sunshine or in darkness.

• LED and sound warning of low battery on the Transmitter.

• Direct access to free technical support for the life of the product.

THE COMPLETE CARGO-SAFE™ KIT INCLUDES:

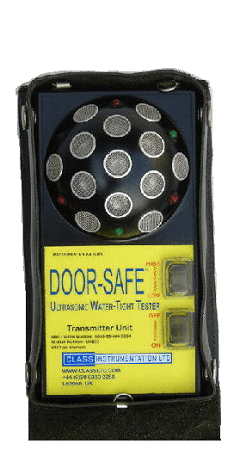

• Ultrasonic Transmitter unit

• Receiver unit

• Hard hat compatible headphones

• 2 Flexible inspection microphones (1 spare)

• Protective IP66 storm-proof leather cases with neck and waist straps for hands free operation

• Telescopic microphone extension, up to 1.15m

• Full operating instructions

• Emergency microphone lead

• Emitter, microphone and extension arm tester

• 12-24V auxiliary power input lead

• Batteries and global charger (with 12V car adaptor)

• 450 x 320 x 100mm carry case

• Total weight of kit in carry case as shown: 2.7kg

• Operational weight 2.4kg